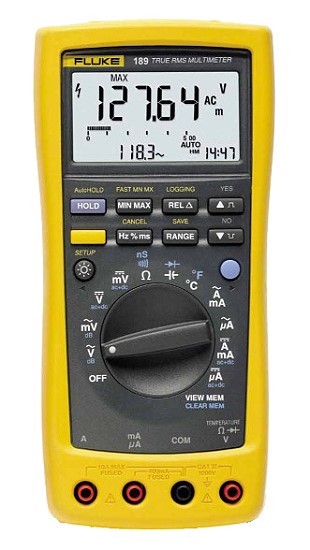

A multimeter is a versatile and essential tool for electrical engineers, technicians, and hobbyists. It measures various electrical parameters such as voltage, current, and resistance, making it a vital tool for diagnosing and repairing electrical systems. Fluke is one of the leading manufacturers of high-quality multimeters used worldwide. However, like any measuring instrument, the accuracy of the measurements provided by a Fluke multimeter can deteriorate over time, making calibration a necessary process. In this article, we will discuss the importance of Fluke multimeter calibration and the consequences of using an uncalibrated multimeter.

What is Fluke Multimeter Calibration?

Calibration is the process of comparing the measurements of a Fluke multimeter with a known standard to determine if it is accurate. A Fluke multimeter calibration is necessary to maintain the accuracy of the measurements provided by the device. It involves adjusting the multimeter’s internal circuits to ensure that the measurements provided are within the manufacturer’s stated accuracy limits.

The Importance of Fluke Multimeter Calibration

There are several reasons why Fluke multimeter calibration is important. The following are some of the reasons:

- Accuracy: The most important reason to calibrate a Fluke multimeter is to ensure that the measurements provided by the device are accurate. An inaccurate measurement can lead to incorrect diagnoses, improper repairs, or even hazardous conditions.

- Compliance: Many regulatory and industry standards require that measuring instruments such as multimeters be calibrated regularly. Compliance with these standards is essential to maintain the safety and reliability of electrical systems.

- Liability: Inaccurate measurements can lead to lawsuits or legal actions, especially in cases where human life is at stake. Calibration is necessary to avoid legal liability in such situations.

- Cost-Effective: Calibration is more cost-effective than replacing a faulty or damaged multimeter. Regular calibration helps identify issues early, allowing for quick repairs or adjustments.

- Reputation: Regular calibration can improve a company’s reputation for providing accurate and reliable services. Clients are more likely to trust a company that regularly calibrates its instruments.

Consequences of Using an Uncalibrated Fluke Multimeter

Using an uncalibrated Fluke multimeter can lead to several consequences, including:

- Inaccurate Measurements: An uncalibrated multimeter can provide inaccurate measurements, leading to incorrect diagnoses and improper repairs.

- Safety Risks: Inaccurate measurements can pose safety risks to individuals and equipment. For example, an inaccurate measurement of high voltage can lead to an electric shock.

- Non-Compliance: Using an uncalibrated multimeter may result in non-compliance with regulatory or industry standards, leading to fines or legal action.

- Costly Repairs: An inaccurate measurement can lead to incorrect repairs, which may cause additional damage to equipment, leading to costly repairs.

Conclusion

In conclusion, calibration is essential for maintaining the accuracy and reliability of Fluke multimeters. Regular calibration ensures that the measurements provided by the multimeter are accurate and comply with regulatory and industry standards. Using an uncalibrated Fluke multimeter can lead to inaccurate measurements, safety risks, non-compliance, and costly repairs. Therefore, it is essential to calibrate Fluke multimeters regularly to avoid these consequences and ensure optimal performance.