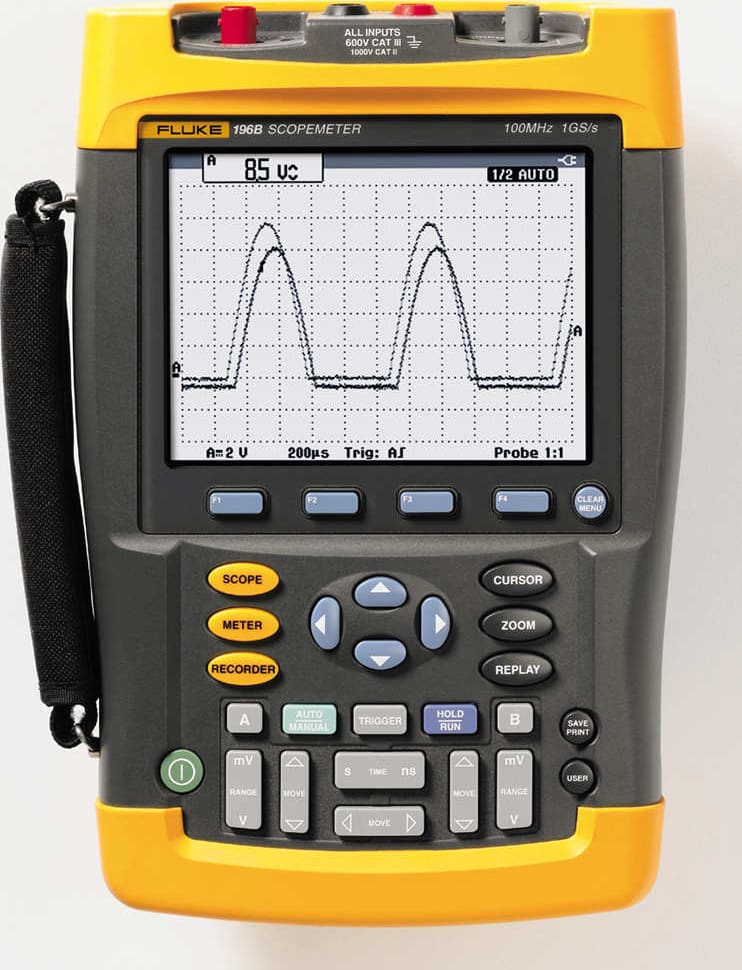

TOTAL Calibration Solutions offers FLUKE 196B calibration services. We understand the importance of your FLUKE 196B SCOPEMETER so you can count on us to get it back to you as fast as possible to prevent any downtime you may experience during the calibration process. TOTAL Calibration Solutions is an ISO/IEC 17025 and ANSI/NCSL Z540-1-1994 accredited Ohio-based calibration company. This accreditation is just one of many ways that shows the fast and capable calibration and repair services that TOTAL Calibration Solutions provides. Our team of highly trained and diverse technicians backed up with some of the most modern calibration instruments available can quickly and efficiently calibrate your FLUKE 196B and any other instruments that that you may have.

TOTAL Calibration Solutions is a customer-based business, and as such strives to make sure that the customer is delivered an excellent experience. Transparency, speed, and quality of service are tenets that TOTAL Calibration Solutions uphold consistently. As such, TOTAL Calibration Solutions provides a customer portal that allows instant access to all previous calibration certificates, as well as other free services that can help manage any instruments in your system. Recall reports, delinquent reports, and other services are all free for customers, which can reduce the stress of calibration and asset management. TOTAL Calibration Solutions is perfectly suited to handle any needs or requests that you may have.

Contact us today for a free quote on your FLUKE 196B SCOPEMETER

TOTAL Calibration Solutions is committed to providing the highest level of calibration, repair, and metrology solutions to meet your needs.

Why is calibration important?

The FLUKE 196B SCOPEMETER is an essential tool for any electrical technician or engineer. It is used to measure, analyze and diagnose electrical systems and components. In order to ensure accurate readings, it is important to calibrate the FLUKE 196B SCOPEMETER regularly.

The calibration process ensures that the SCOPEMETER is measuring accurately and that the readings are consistent. This is important because the readings are used to diagnose problems and make decisions about repairs and maintenance. If the readings are not accurate, then the decisions made may be incorrect and can lead to further problems and even safety risks.

Calibrating the FLUKE 196B SCOPEMETER is a relatively simple process. The user should first check the accuracy of the instrument by comparing the readings to a known reference. This can be done by connecting the SCOPEMETER to a known voltage source and verifying that the readings match the expected values.

If the readings are not accurate, then the user should adjust the calibration settings on the SCOPEMETER. This can be done by accessing the calibration menu and adjusting the settings until the readings match the expected values.

It is important to note that the calibration settings should only be adjusted if the readings are not accurate. If the readings are accurate, then the calibration settings should not be changed.

In addition to verifying the accuracy of the readings, the calibration process also ensures that the SCOPEMETER is functioning correctly. The calibration process can help to identify any issues with the instrument, such as faulty wiring or components.

In summary, the calibration of the FLUKE 196B SCOPEMETER is an important process that should be performed regularly. It ensures that the readings are accurate and that the instrument is functioning correctly. Without proper calibration, the readings may be inaccurate and can lead to incorrect decisions and further problems.